Apollo Ball Valves

|

Apollo Ball Valves |

|

| Series 70, 71, 82: ºÍÅÇÒÅìǷͧàËÅ×ͧºÃ͹«ì (Bronze Ball Valves) |

|

|

|

|

|

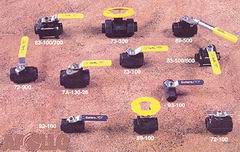

70-100 Series

70-100 Series—Conbraco’s most versatile, most

used ball valve. Reliable shutoff, easy operation.

Available with above features and ratings, or with

choice of nearly 30 options. Sizes 1/4” to 4”.

|

|

70-100-27 Series

70-100-27 Series—Same as 70-100 but with optional

latch-lock handle. Latch secures handle in open or

closed position, reducing risk of mishap. Satisfies OSHA

requirements. Sizes 1/4” to 3”.

|

|

70-200 Series

70-200 Series—Solder-end valve designed for softsoldering

into lines without disassembly so valve can

be installed without disturbing seats and seals.

Several options available. Sizes 3/8” to 3”.

|

|

70-300 Series

70-300 Series—Same as 70-100 but with single

union end. Fluorocarbon O-Ring sealed union

requires only light torque for proper seal; threaded

or solder end. Sizes 1/4” to 2”.

|

|

71-100 Series

71-100 Series—Same as 70-100 but with mounting

pad for optional spring-return handle, actuator or

panel mounting. Sizes 3/4” to 3”.

|

|

70-600 Series |

|

82-100 Series

82-100 Series—3-piece full port ball valve; inline

repairable, adjustable packing gland. Sizes 1/4”

to 4”. NPT threaded ends.

|

|

82-200 Series |

|

¡ÅѺ¢Ö鹺¹ÊØ´ - Back To TOP ¢ÍÃÒÂÅÐàÍÕ´à¾ÔèÁàµÔÁ·Ò§ e-mail : epmc@epmc.co.th |

| Series 72, 73, 89, 93: ºÍÅÇÒÅìÇàËÅç¡à˹ÕÂÇ (Carbon Steel Ball Valves) |

|

|

|

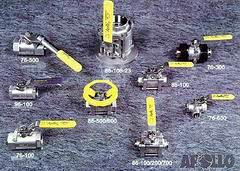

72-100 Series

72-100 Series—High-pressure valve with heavy-duty

lever, body rated 3000 psig WOG, cold non-shock,

150 psig saturated steam. Nitride corrosion protection.

Sizes 1/2” to 2”; all models except 2” feature full port.

|

|

72-900 Series

72-900 Series—Straight-thread, O-Ring boss valves

meet SAE 11926 specs. Ideal for reducing fluid leakage

and energy loss in automotive applications and machining

and hydraulic systems. Sizes 1/4” to 1-1/2”are full

port; 2” is standard port; optional locking kit available. |

|

73A Series

73A Series—Forged A105 Low Carbon Steel valve with

nitride corrosion protection, adjustable packing gland,

blow-out proof stem. Two-piece design, NACE compliant

when ordered with SS trim (73A-140 series). Standard

handle options. Sizes 1/4” – 2”. |

|

73-300 Series |

|

83R-100/200/700 Series

83R-100/200/700 Series—3 Piece full port #1000

CWP valves with ISO 5211 mounting pad, advanced

packing design. Threaded (-100), socket weld (-200) and

butt weld (-700) versions. Many options, including –AR

actuator-ready with live-loading. Sizes 1/2” – 2”. |

|

89-500 Series |

|

¡ÅѺ¢Ö鹺¹ÊØ´ - Back To TOP ¢ÍÃÒÂÅÐàÍÕ´à¾ÔèÁàµÔÁ·Ò§ e-mail : epmc@epmc.co.th |

| Series 76, 96: ºÍÅÇÒÅìÇÊ൹àÅÊ (Stainless Steel Ball Valves) |

|

|

|

76-100 Series

76-100 Series—Stainless steel valves with threaded

ends, blowout-proof stem design and investment cast

components, RPTFE seats, stuffing box ring. Meets

NACE MR-01-75. Sizes 1/4” to 3”. |

|

76-300 Series

76-300 Series—Double union end stainless steel

ball valve; meets NACE MR-01-75. Heavy-duty quarter-

turn 304 SS handle with vinyl. Sizes 1/2” to 2”. |

|

76-500 Series

76-500 Series—Stainless steel ball valve with spring

return handle. MPTFE seats, stuffing box ring. Specify

(-01) suffix for return to close or (-08) suffix for return

to open. Sizes 1/4” to 2”. |

|

76-600 Series |

|

76F Series

76F Series—Economy stainless steel full port valve, 1000#

CWP rating. Threaded ends, blowout proof stem, investment

cast body, 316 SS components, including stainless handle.

RPTFE seats and long-life MPTFE packing. Sizes 1/4” – 2”. |

|

76 AR Series |

|

85R-100/200 Series

85R-100/200 Series—3 Piece standard port 1000#

CWP valves with ISO 5211 mounting pad, advanced packing

design. Threaded (-100) and socket weld (-200) versions.

Many options, including –AR actuator-ready with live-loading.

Sizes 3/4” – 2”. |

|

86R-100/200/700 Series

86R-100/200/700 Series—3 Piece full port 1000# CWP

valves with ISO 5211 mounting pad, advanced packing

design. Threaded (-100), socket weld (-200) and butt weld

(-700) versions. Many options, including –AR actuator-ready

with live-loading. Sizes 1/4” – 2”. |

|

86-500/600 Series

86-500/600 Series—High-pressure 3-piece full port

valves. 1500 psig WOG, cold non-shock, 150 psig steam.

In-line repairable, -500: threaded end; -600: socket weld.

Sizes 1/4” to 2”. Round handle, option -15 shown, reduces

possibility of accidental opening or closing. |

|

96 Series |

|

¡ÅѺ¢Ö鹺¹ÊØ´ - Back To TOP ¢ÍÃÒÂÅÐàÍÕ´à¾ÔèÁàµÔÁ·Ò§ e-mail : epmc@epmc.co.th |

| Series 87A, 88A: ºÍÅÇÒÅìÇ˹éÒá»Å¹ ANSI (ANSI Flanged Ball Valves) |

|

|

|

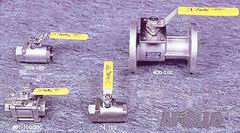

87A Series

87A-100 Series—Stainless Steel class 150 Flanged, Regular

Port Valves. Unibody to 2”, easily-repaired split body 3” and

larger. (87B series is unibody design 3” and 4”). Standard stem

grounding and locking device. Includes ISO 5211 mounting

pad. Meets many standards, including NACE, and API 607

4th Ed. when ordered as –24. Available in 1-1/2”-10”. 87A-200 Series—Class 150 full port stainless valves. Split body design for easy repair, includes grounding, locking device, and ISO 5211 actuator mounting pad. Available in sizes 1/2” - 12”, with a broad standards compliance. A true engineered design with every desirable feature addressed. 87A-700 Series—Class 300 standard port flanged valve with features identical to 87A-100 above. 87A-900 Series—Class 300 full port stainless valve, with features of 87A-200 above. |

|

88A Series

88A-100 Series—Carbon Steel Class 150 Flanged, Regular

Port Valves. Unibody to 2”, easily-repaired split body 2-1/2”

and larger. (88B series is unibody design 3” and 4”). Standard

stem grounding and locking device. Includes ISO 5211 mounting

pad. Meets all standards, including NACE when ordered

with SS trim, and API 607 4th Ed, when ordered as –24.

Available in 1-1/2”-10”. 88A-200 Series—Class 150 full port carbon valves. Split body design for easy repair, includes grounding, locking device, and ISO 5211 actuator mounting pad. Available in sizes 1/2” - 12”, with full standards compliance. A true engineered design with every desirable feature addressed. 88A-700 Series—Class 300 standard port carbon steel flanged valve with features identical to 88A-100 above. 88A-900—Class 300 full port carbon steel valve, with features of 88A-200 shown above. |

|

87A-400/500/600 Series

87A-400 Series—Alloy 20 class 150 flanged standard port ball valves. 87A-500 Series—Alloy 20 class 150 flanged full port ball valves. 87A-600 Series—Alloy 20 class 300 flanged full port ball valves. See Alloy Ball Valves section for more details. |

|

452/453 Series 453 Series—Class 150 full port carbon steel ball valves with extended bonnet. See Specialty Valves section for more details. |

|

¡ÅѺ¢Ö鹺¹ÊØ´ - Back To TOP ¢ÍÃÒÂÅÐàÍÕ´à¾ÔèÁàµÔÁ·Ò§ e-mail : epmc@epmc.co.th |

| Series 72, 73, 89, 93: ºÍÅÇÒÅìÇâÅËÐÍÑÅÅÍ (Alloy Ball Valves) |

|

In addition to stainless and carbon steel, Conbraco routinely pours special alloys such as Alloy 20, Hastelloy®, Ni-Cu and nickel at its state-of-the-art investment-casting foundry in Conway, SC. Hastelloy, Ni-Cu and titanium are primarily used in the company’s top entry ball valve line but can be used for end entry valves on special orders. The valves shown on this page are standard Apollo alloy ball valves. |

|

74-100 Series

74-100 Series—Chemical resistant nickel ball valve, threaded end, blowout-proof stem, 304 SS lever and grip. Investment cast components. Sizes 1/2” to 2”. |

|

399-100 Series

399-100 Series—Alloy 20 2-piece threaded valve with

304 SS and vinyl lever and grip. Investment cast with

blowout-proof stem, adjustable packing gland; many

options. Sizes 1/4” to 2”. Shown with option -27, latch

lock handle. |

|

87A-400/500/600 Series

|

|

401R-100/200 Series -100: threaded; -200: socket weld. Sizes 1/2” to 2”. Shown with lock plate, option -19 which allows valve to be locked in open or closed position. |

|

¡ÅѺ¢Ö鹺¹ÊØ´ - Back To TOP ¢ÍÃÒÂÅÐàÍÕ´à¾ÔèÁàµÔÁ·Ò§ e-mail : epmc@epmc.co.th |

| Series Specialty: ºÍÅÇÒÅìǾÔàÈÉ (Specialty Ball Valves) |

|

|

|

¡ÅѺ¢Ö鹺¹ÊØ´ - Back To TOP ¢ÍÃÒÂÅÐàÍÕ´à¾ÔèÁàµÔÁ·Ò§ e-mail : epmc@epmc.co.th |

| Series TOP ENTRY: ºÍÅÇÒÅìǶʹ´éÒ¹º¹ (Top Entry Ball Valves) |

|

|

|

Flanged Series : Top Entry Ball Valves

Flanged Series - In 150, 300 and 600 ANSI Class. Materials: Alloy 20, carbon steel, Hastelloy C, M35-1, nickel, stainless steel and titanium. Sizes 1/2 " to 10".

|

|

Socket Weld & NPT Series : Top Entry Ball Valves

NPT and Socket Weld Series - Available in 300 ANSI Class sizes 1/2 " through 3"; and 600 ANSI Class 1/2" through 2". Materials: Alloy 20, carbon steel, Hastelloy C, M35-1, nickel, stainless steel and titanium.

|

|

Full Port Flanged Series : Top Entry Ball Valves

A full-port configuration available in sizes 1 " through 8".

The new ANSI Class 150, 300 and 600 valves' full-port design delivers increased throughput. They're ideal for harsh processes involving abrasives, slurries, corrosives, thermal fluids and clean services, such as hydrogen peroxide and oxygen.

|

|

Butt Weld Series : Top Entry Ball Valves

Butt Weld Series - Available in ANSI Class 300 and Class 600 to 8 " size. Schedule 10, 40 and 80 pipe ends offered. A full range of body, seat and seals materials are available.

|

| ºÍÅÇÒÅìÇËØéÁ»ÅÍ¡ä͹éÓ (Steam Jacketed Top Entry Ball Valves) |

|

Steam Jacketed Apollo® Top Entry Ball Valves

Conbraco’s Apollo ® Top Entry Ball Valves are ideally suited for jacketed applications. The top entry concept allows for continued access to stem packings and valve internals for ease of maintenance without disturbing the jacket itself or removing

the valve from the pipeline.Partial jacketing (Option “PJ”) may be used on standard valves. Partial jacketing is applied just to the center section of the valve and does not incorporate the neck area or flanges of the valve. It is generally specified to allow the use of standard flanges and retain conventional flange bolting. Fully jacketed, standard flange valves have modified flanges with blind tapped stud holes in place of the ordinary through holes. |

|

Steam Jacketed Apollo® Top Entry Ball Valves

Welded full jacketing may be applied to valves with standard flanges (Option “FS”) or oversize flanges (Option “FO”).

Valves and jacketing can be supplied in a variety of materials. Common materials are stainless valves with stainless jackets,

but exotic combinations such as Alloy 20 valves with carbon steel flanges and carbon steel jacketing have been supplied to meet the performance and cost requirements for specific applications. |

|

|

Steam Jacketed Apollo® Top Entry Ball Valves

Clamp-on jacketing (Option “CJ”) offers flexibility not available in the other configurations. Clamp-on jacketing can be applied

to valves already in service, or can be removed and reinstalled on a replacement valve or another similar valve in another

application. Clamp-on jackets can be supplied as a weldment or in cast aluminum. A heat transfer compound can be applied

between the clamp-on jacket and valve to improve its efficiency. Combining these jacketed valves with extended bonnets for safe convenient operation, and adding carbon graphite seats or ceramic balls and seats enables the valve to handle a broad range of viscous materials. |

|

¡ÅѺ¢Ö鹺¹ÊØ´ - Back To TOP ¢ÍÃÒÂÅÐàÍÕ´à¾ÔèÁàµÔÁ·Ò§ e-mail : epmc@epmc.co.th |